|

|

|||

|

|

|||

|

Racking Shuttle SystemIs a semi-automated storage solution for the handling - Efficient system of compact storage for warehouses with low levels of SKU - Optimisation of storage, loading and unloading stages - Low level of risks or stress to the warehouse operating staff - Low level of risks or damage to the equipment -loading machinery and racks, - Removes the need for specialist forklift trucks |

|

|

|

All handling of the goods within the channels is carried out using |

|

||

|

|

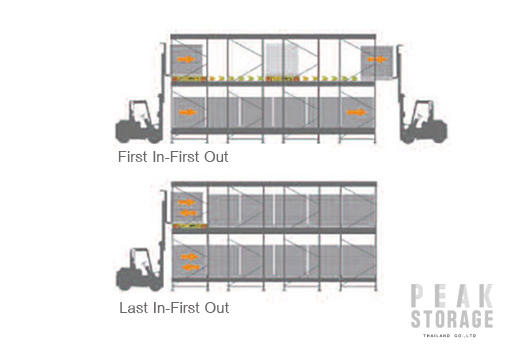

The pallets are placed on an Pallet Shuttle (a battery powered pallet cart) The Pallet Shuttle System can work either as FIFO or as LIFO, - Cold Storage - Food Production - Meat Processing - Beverage Production and Distribution - All Drive-In / Drive-Through Racking users |

||

SpecificationsThe pallet shuttle is powered by a Lithium battery. Near the end of CE marked and made in Italy, the pallet shuttle comes in a range |

|